Machine Room Less

The main benefit for the MRL is eliminating the need for a machine room by placing the machine at the top of the shaft. Most locations in the USA (excluding New York City) require a small, closet-style space to house the controller and other electrical equipment. The MRL comes with a gearless machine that offers a quick, smooth, and quiet ride while being energy and cost efficient.

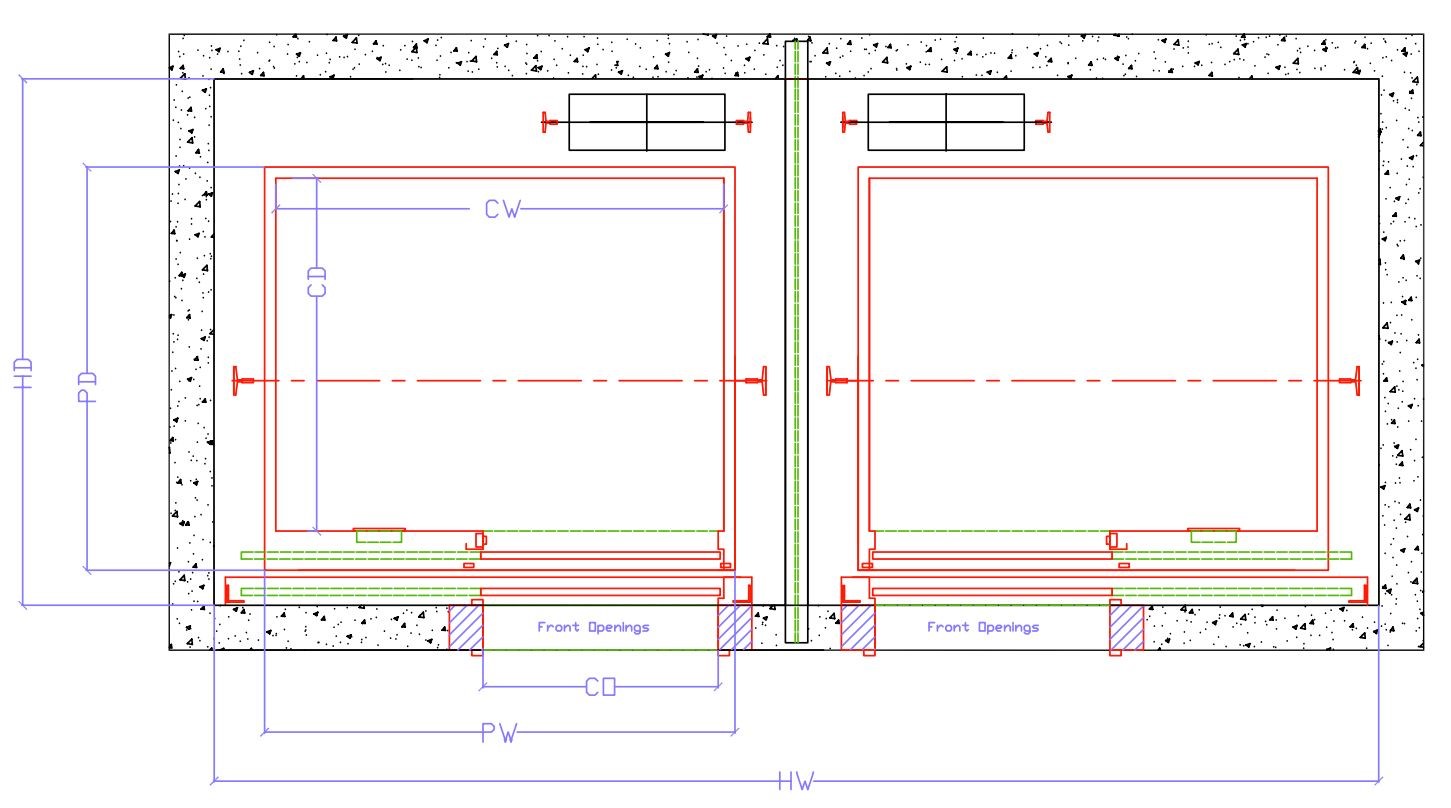

Side-Mounted Counterweight

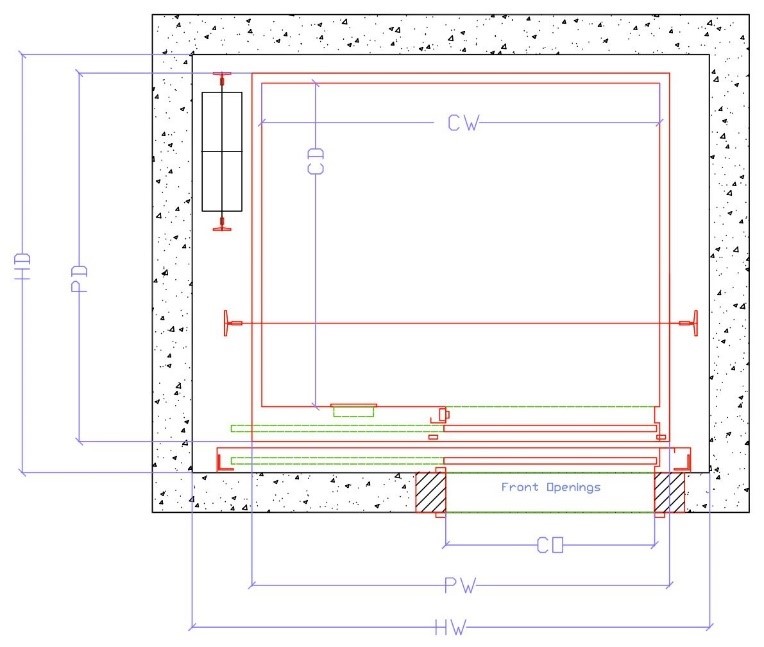

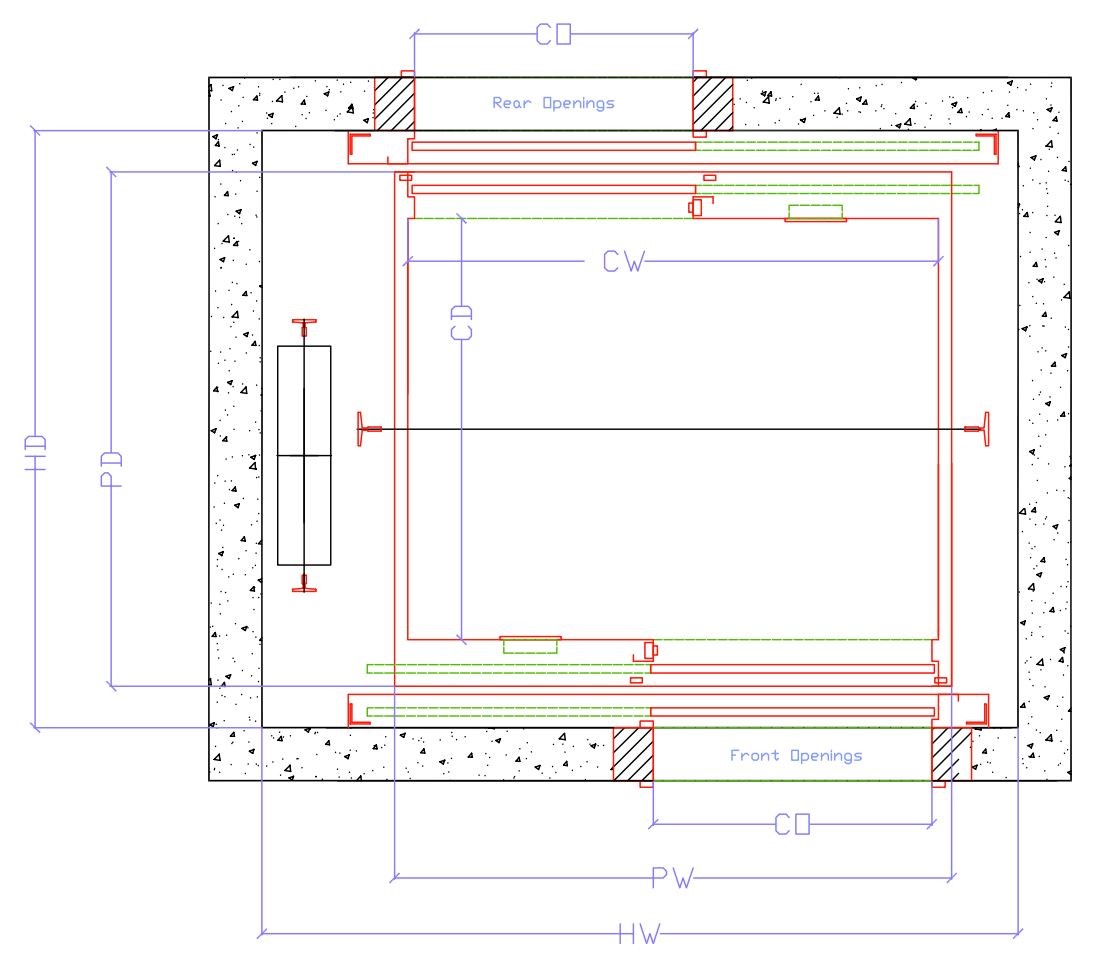

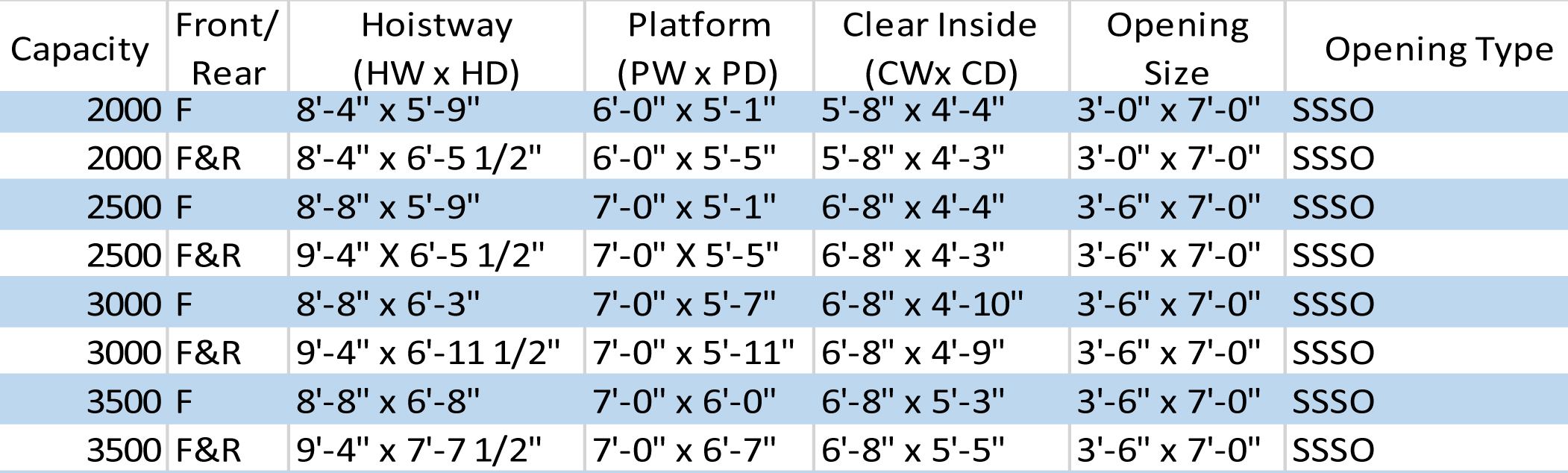

The side-mounted counterweight design can be used for new construction or replacing existing equipment due to its flexibility to be used with front opening or front/rear opening elevators. This arrangement has the counterweight located on either side of the platform. This is one of our most manufactured arrangements.

Above features the counterweight side mounted, seen with Front (left) or Front and Rear (right).

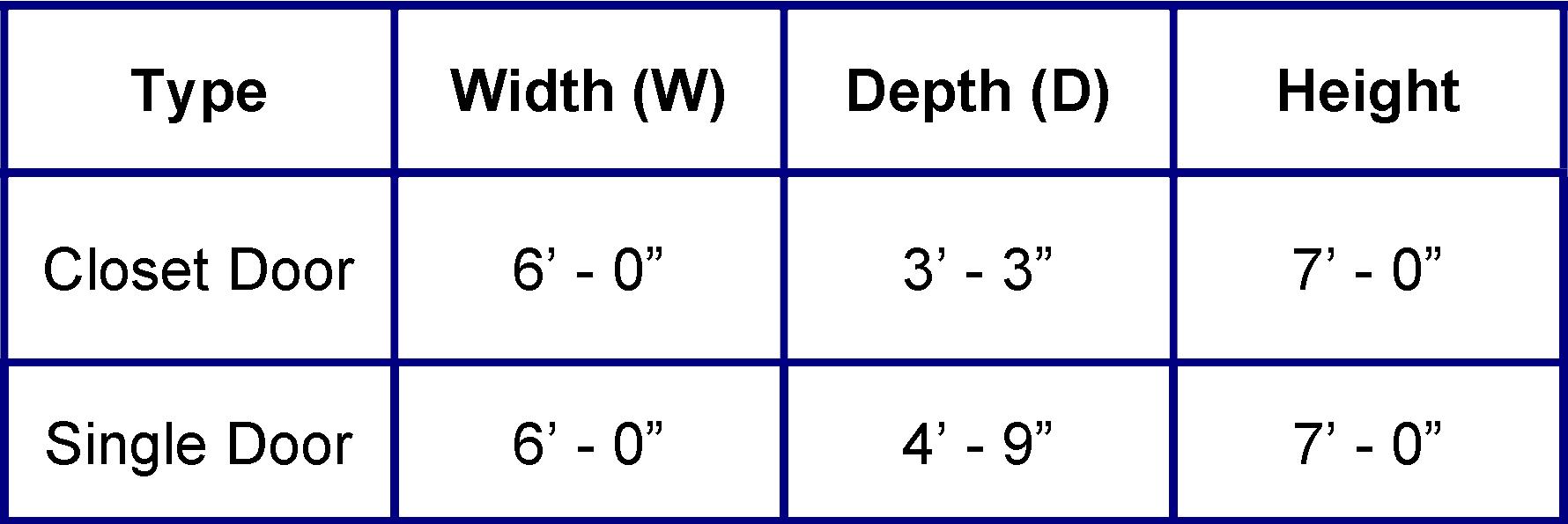

1 - Different shaft sizes from those listed in the above table can be accommodated by Amerivator Systems Corporation. Please contact our engineering department to determine the capacity options available to you at your given dimensions.

2 - Pocketing a door will reduce the required hoistway depth for a given capacity.

3 - All dimensions are for information only and cannot be used for construction without being confirmed by Amerivator Systems Corporation.

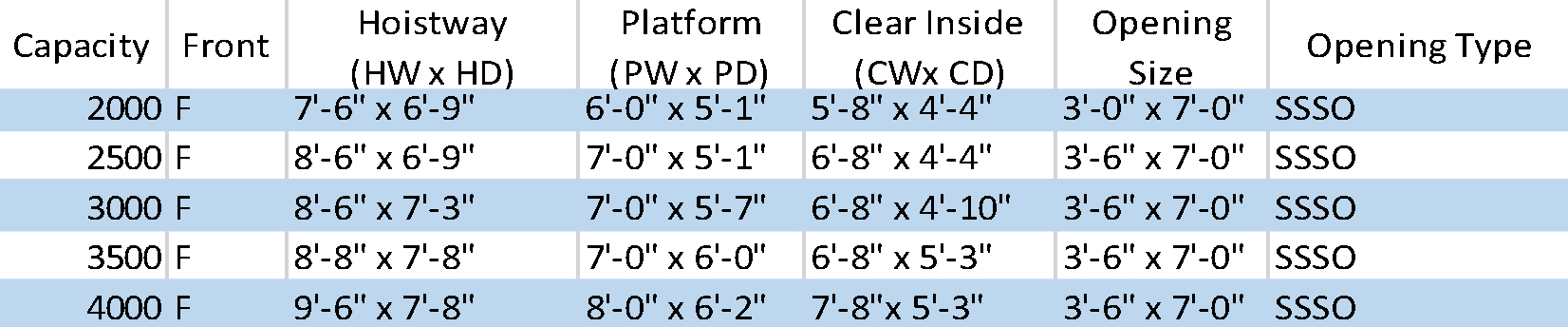

Rear-Mounted Counterweight

Amerivator recommends the rear- mounted design for front opening cars only. It serves as a replacement for existing corner-post arrangements, or as a solution for hoistways with width restrictions. The counterweight is located at the rear of the shaft with overslung sheaves in a diagonal arrangement.

Above features a duplex shaft with two rear- mounted counterweight with overslung sheaves. Any combination of rear-mounted, side-mounted, or corner post can be included in a duplex. Contact our engineering department for duplex options.

1 - Different shaft sizes from those listed in the above table can be accommodated by Amerivator Systems Corporation. Please contact our engineering department to determine the capacity options available to you at your given dimensions.

2 - Pocketing a door will reduce the required hoistway depth for a given capacity.

3 - All dimensions are for information only and cannot be used for construction without being confirmed by Amerivator Systems Corporation.

Cornerpost

Above features a cornerpost arrangement with the counterweight located at the side, a front and side opening and car rails located in two corners of the shaft.

Cornerpost configurations are designed on a per-job basis by our engineering department. Due to the involvedness of the design, we do not provide standard dimensions for these applications. Please contact our engineering department to see if a cornerpost design would suit your job.

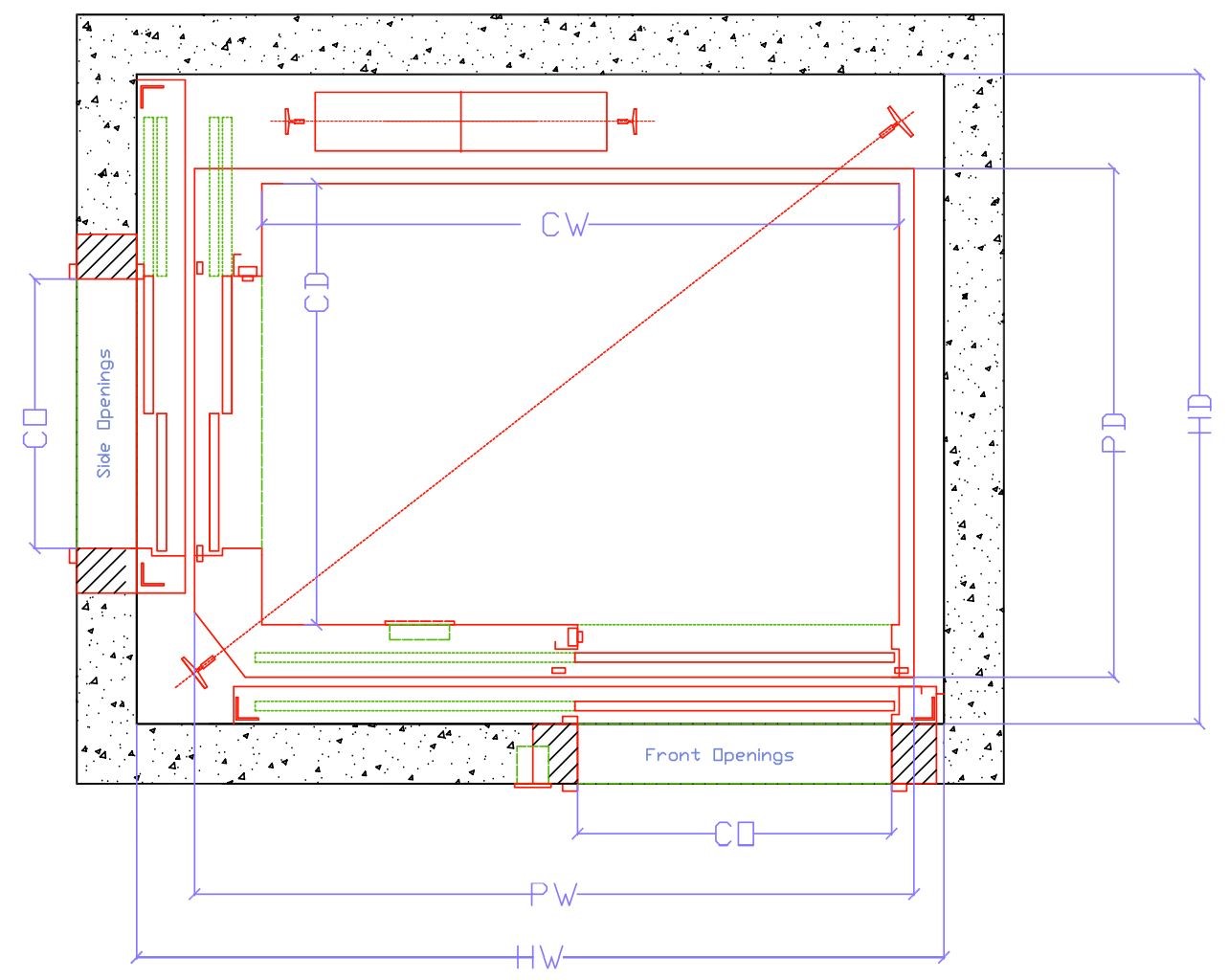

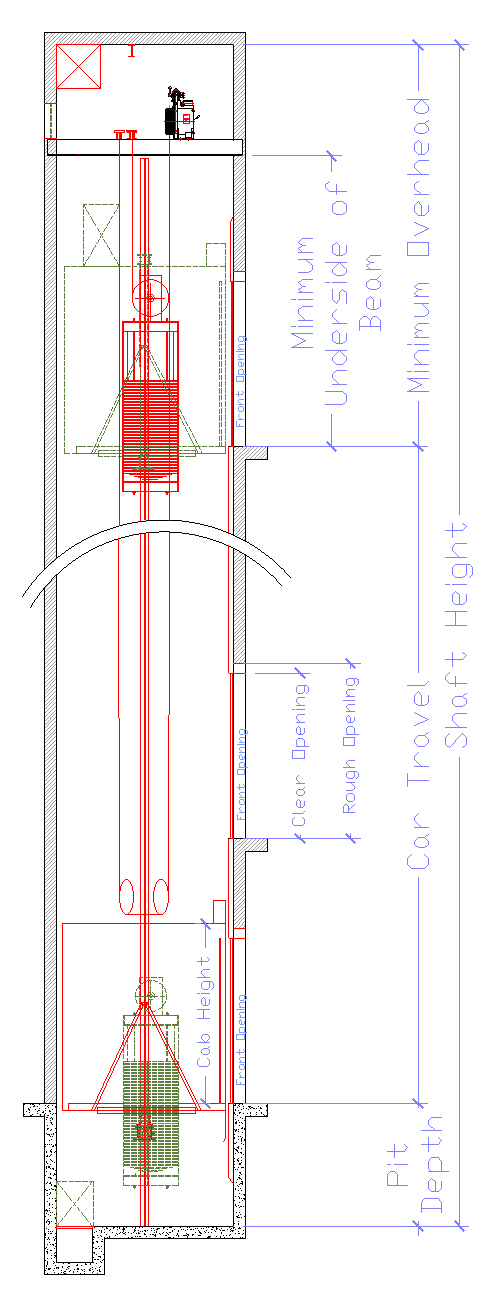

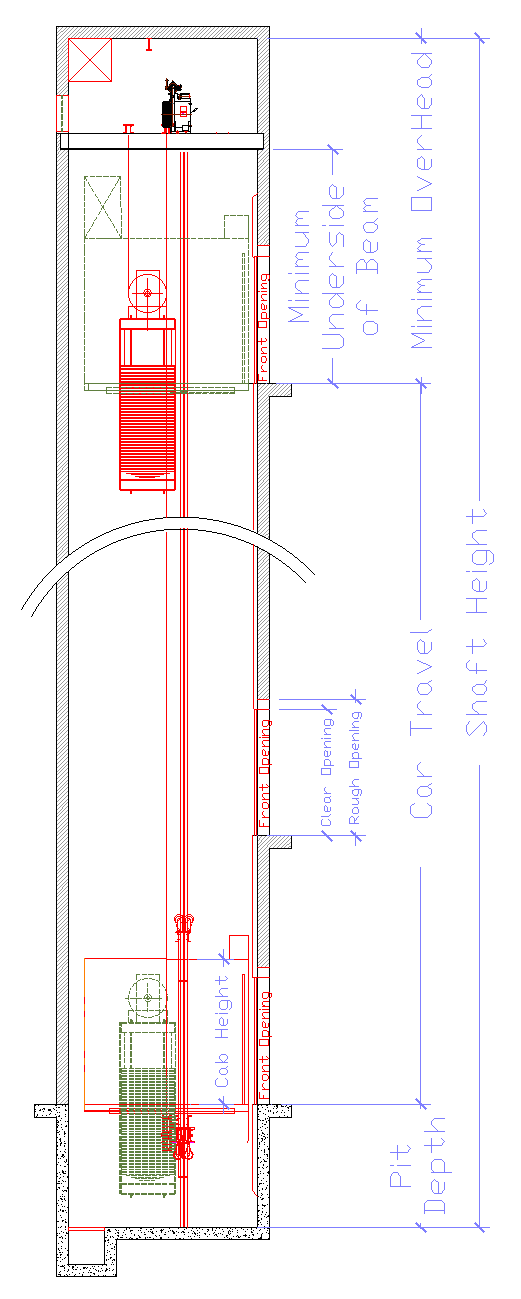

Pit & Overhead Requirements

1 - Note that any increase in cab height will result in an equal increase in the “Minimum Overhead” and “Minimum to Underside of Machine Beams”.

Shaft layout of overslung sheave configuration.

Shaft layout of underslung sheave configuration.

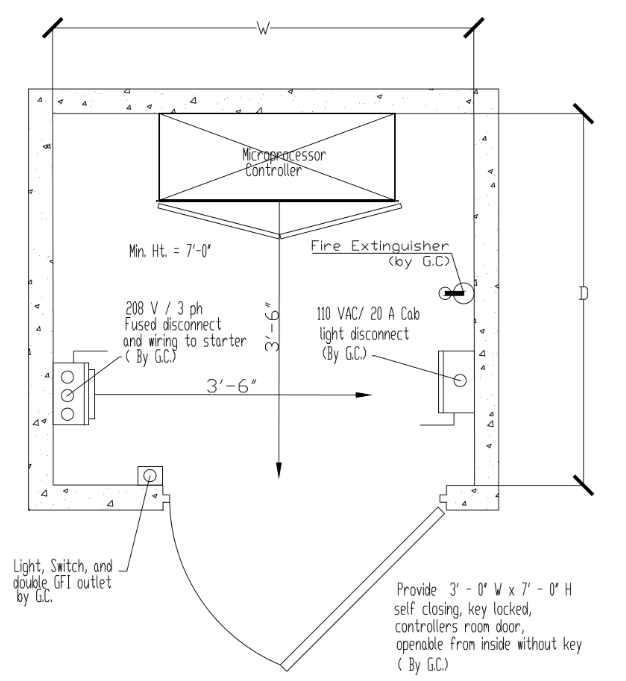

Control Room Requirements

Since the MRL machine is placed within the shaft, the need for a large machine rom is eliminated. Most locations in the United States (excluding New York City) require only a small, closet-style space to house the controller and other electrical equipment for the elevator, such as a fused disconnect and the cab light disconnect.

A standard machine room layout. Custom designs are available upon request. Please contact our engineering department with any questions.